At Exact Engineering, we like to approach engineering problems in a simple yet deterministic manner. Essentially, we follow a three-step process. First, define requirements. Second, commence design guided by the requirements. Third, perform structural/thermal/dynamic analysis to determine if the design meets the requirements. Often, the analysis results will require a design change and thus the process tends to be iterative. The end goal is a design that meets the requirements with the fewest iterations at the lowest engineering costs.

The key to keeping the cost low and shortest time to market is a well defined set of requirements. Requirements are necessary for determining the big three:

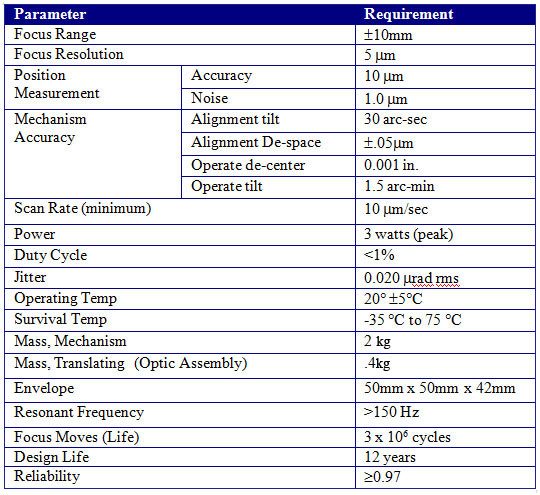

Often a client will come to us with an initial concept. In this case, we collaborate very closely with them to establish a requirements document. Well-defined requirements not only save time and money but also yield the best product. Pictured is a sample of a concise and cohesive set of performance requirements for a small mechanism. Although not all-inclusive, this is a good example of a set of requirements from which one could initiate design.

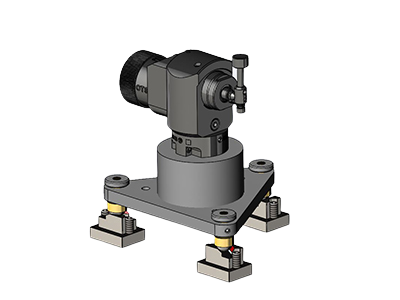

From the established set of requirements, the design process can be fully engaged and will often will require the application of a variety of engineering disciplines. As an example, using the requirements above the design process may include:

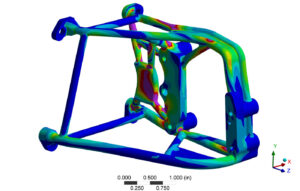

Once the design has progressed to the level of best engineering judgement, it is often necessary to perform structural/thermal/dynamic analysis as necessary to optimize the design. This analysis can be as simple as ensuring a static structural component can withstand a given load or complex as a shock analysis of a product as in a drop test. Regardless of the complexity, we have the tools and more importantly the expertise to solve your analysis problems. Below is a summary of our analysis capabilities.

If you have any questions regarding our products or services, please send us a message using the form below. We can also be reached by phone at 603-319-4955.

We look forward to hearing from you.

For a Quote on your next project, please fill out the form below, send us an email, or simply give us a call. If you are looking to purchase one of our products, please visit this link. We’re looking forward to working with you. 603-319-4955