Enjoy Greater Confidence with our Engineering Analysis Services

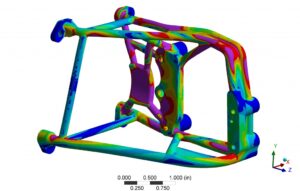

At Exact Engineering we use the ANSYS Workbench suite of finite element analysis software (FEA) which is well known as the industry standard.

The response of structures and components undergoing changing environmental conditions must be well understood to ensure a design will meet requirements. At Exact Engineering, we conduct structural, dynamic and thermal analysis to predict a system’s response to environmental impacts. Performing analysis at the necessary stages adds significant value to the product by ensuring the product performs to requirements before manufacture and assembly.

That said, unnecessary or inappropriate analysis costs both time and money. On complex and even simple designs, without experience and expertise, it is difficult to determine the necessary analysis and properly implement it. “Analysis paralysis” can cripple a projects schedule and generate high-cost overruns.

So how do we avoid analysis paralysis? With over 25 years of proven experience analyzing structures ranging from precision optical systems on board the Hubble Space Telescope to pointing and tracking systems flown on UAVs, we have the experience necessary to avoid analysis paralysis.

We have a number of tools for solving static structural, dynamic structural and thermal analysis problems. These range from closed form analytical solutions to finite element analysis (FEA) for more complex problems. We use the most advanced engineering software tools available today, including the ANSYS Workbench suite for finite elemental analysis, widely-recognized as the industry standard for FEA applications.

Types of Analysis: Linear Analysis vs. Non-Linear Analysis

Linear structural analysis is the most straightforward method of analysis. For simple geometries we can apply known analytical equations which are quick to solve and provide exact results. We always encourage our clients to use materials that behave linearly as this results in lower engineering and manufacturing costs while improving reliability. We believe the simplest solution is often the most robust and elegant.

Of course if your project requires non-linear materials and geometries, we are well equipped to engineer the best solution.

Modal: Also known as natural frequency analysis, this method is used to determine the natural resonant frequencies or “modes” of a structure. Knowing the modes of a structure are crucial in determining how it will respond to an input. If an input frequency such as a varying force matches a natural mode of the structure, the structure will be excited and could lead to failure. The collapse of the Tacoma Narrows Bridge in 1940 is a classic example of a structure responding to an input that excites its natural modes.

Harmonic: Harmonic analysis is used to predict dynamic behavior of structures undergoing constant cyclic loading due to forcing functions. Harmonic analysis can be used to determine if a system will survive resonance, fatigue, and other detrimental effects of forced vibrations. Rotating machinery falls under this category for example, turbines, disc drives, electric motors and pumps, etc.

Random Vibration: Also known as “Response Spectrum Analysis,” this analysis is used to determine the response of structures undergoing random or time-dependent loading conditions such as earthquakes, wind loads, ocean wave loads, or jet engine thrusts. We would use random vibration analysis in testing input vibrations such as those generated by a space shuttle launch or a vehicle traveling over a bumpy road.

Transient: Transient dynamic analysis is a technique used to determine the dynamic response of a structure under the action of any general time-dependent loads. Transient dynamics analyses are use to determine the time-varying displacements, strains, stresses, and forces in a structure as it responds to any combination of static and time varying loads, while simultaneously considering the effects of inertia or damping. One example is a time varying sinusoidal shock impulse applied to a structure whose response varies with time. Seismic analysis falls into this category as well.

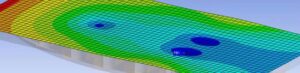

Thermal: Thermal effects can cause structures to expand and contract, and can severely impact the performance of optical and electrical systems, especially those with active components such as lasers and microprocessors. Identifying and understanding these effects during the prototyping phase saves time and money.

If you have any questions regarding our products or services, please send us a message using the form below. We can also be reached by phone at 603-319-4955.

We look forward to hearing from you.

For a Quote on your next project, please fill out the form below, send us an email, or simply give us a call. If you are looking to purchase one of our products, please visit this link. We’re looking forward to working with you. 603-319-4955